Aluminum repair techniques are specialized practices for restoring and maintaining aluminum automotive components like car bodies, fenders, and panels. Common issues addressed include dents, scratches, and deformities caused by impacts or wear and tear. Skilled professionals use advanced tools and methods, combining manual and modern technology, to ensure structural soundness and preserve the vehicle's aesthetic appeal. These techniques are ideal for both industrial applications and automotive restoration, extending the lifespan of bodywork, maintaining strength and durability, and enhancing vehicle market value through sustainable practices. Beyond automotive uses, aluminum repair techniques are employed in construction and manufacturing to fix building frames, machinery, and equipment, reducing costs and minimizing environmental impact.

Aluminum repair techniques have emerged as game-changers in various industries, offering efficient and sustainable solutions for damaged aluminum components. This article delves into the world of aluminum repairs, exploring what these techniques entail and how they provide significant advantages over traditional methods. From enhancing structural integrity to reducing environmental impact, understanding these benefits is crucial for businesses seeking innovative ways to maintain and repair aluminum structures.

- What are Aluminum Repair Techniques?

- Advantages of Using Aluminum Repair Techniques

- Applications and Industries Benefiting from Aluminum Repair Techniques

What are Aluminum Repair Techniques?

Aluminum repair techniques refer to a set of specialized practices designed to restore and maintain aluminum automotive components, such as car bodies, fenders, and panels. These techniques involve various methods to address common issues like dents, scratches, and deformities that may arise over time due to impacts or regular wear and tear. The process often requires skilled professionals who employ advanced tools and materials to accurately fix these problems, ensuring the integrity and aesthetic appeal of the aluminum surfaces.

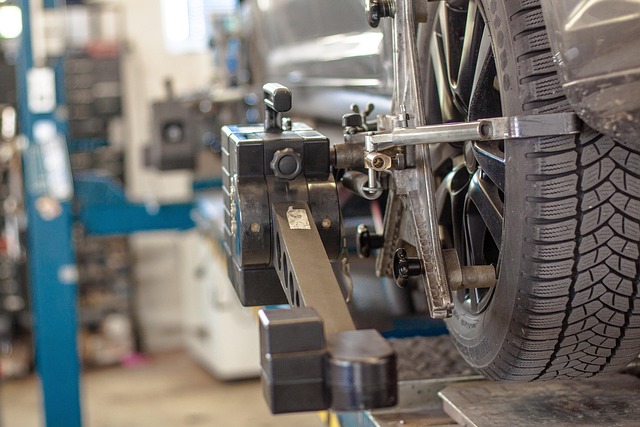

One prevalent method in aluminum repair is dent removal, where experts carefully manipulate the metal back to its original shape without causing further damage. Car bodywork services specializing in aluminum often use a combination of manual techniques, such as malletting and clamping, along with modern technology like pneumatic tools and heated machines to achieve precise results. This meticulous approach not only enhances the structural soundness of the vehicle but also preserves its overall look, making it an essential service provided by auto body shops catering to aluminum-bodied cars.

Advantages of Using Aluminum Repair Techniques

Aluminum repair techniques offer numerous advantages for both industrial applications and automotive restoration. One of the key benefits is their ability to preserve the structural integrity of aluminum components, which are increasingly used in modern car bodywork due to their lightweight properties. These repair methods ensure that damaged or dented vehicle bodywork can be effectively restored without compromising strength and durability.

Additionally, aluminum repair techniques provide an efficient and cost-effective solution for car paint repair, extending the lifespan of vehicles. The versatility of these techniques allows for precise restoration, matching the original finish seamlessly. This is particularly valuable in maintaining the aesthetic appeal of vehicles, enhancing their overall market value. Whether it’s repairing dents, restoring panels, or refinishing surfaces, aluminum repair techniques offer a sustainable and professional approach to vehicle bodywork maintenance.

Applications and Industries Benefiting from Aluminum Repair Techniques

Aluminum repair techniques have found applications across a wide range of industries where lightweight and durable materials are essential. The automotive sector, in particular, has greatly benefited from these advanced repair methods, especially in the realm of auto collision repair. Modern vehicles increasingly incorporate aluminum components for their strength-to-weight ratio, making traditional repair approaches less feasible. Aluminum repair techniques offer precise restoration, ensuring structural integrity and vehicle safety after collisions.

Beyond automotive repair, construction and manufacturing also utilize aluminum repair techniques to maintain the performance and longevity of their products. This includes repairing building frames, machinery, and other equipment that relies on aluminum for its strength and corrosion resistance. By employing these innovative repair methods, industries can extend the lifespan of their assets, reduce costs associated with replacement, and minimize environmental impact by promoting recycling and reutilization.

Aluminum repair techniques offer a sustainable and cost-effective solution for various industries, ensuring the longevity of aluminum structures. By understanding and adopting these methods, businesses can reduce waste, save resources, and contribute to a greener future while maintaining high-quality materials. The versatility of these techniques allows for efficient repairs in diverse applications, making them an indispensable toolset for professionals working with aluminum.